Picture a row of new homes gleaming under a pale spring sky; clean lines, wide windows, everything tuned toward lower energy use. Behind that glass sits one of the quiet revolutions in modern housing: vacuum glazing.

As the UK edges closer to tougher energy-efficiency targets, this technology is moving fast from niche to necessity. At The Vacuum Glazing Network Ltd (VGN), we’ve seen the shift unfold firsthand. Architects are using it to design slimmer, brighter façades. Developers are hitting energy benchmarks without redesigning entire builds. Homeowners are cutting heating bills without shutting out natural light. It’s not hype, it’s momentum and a practical step toward low-carbon living.

Understanding Vacuum Glazing (VIG)

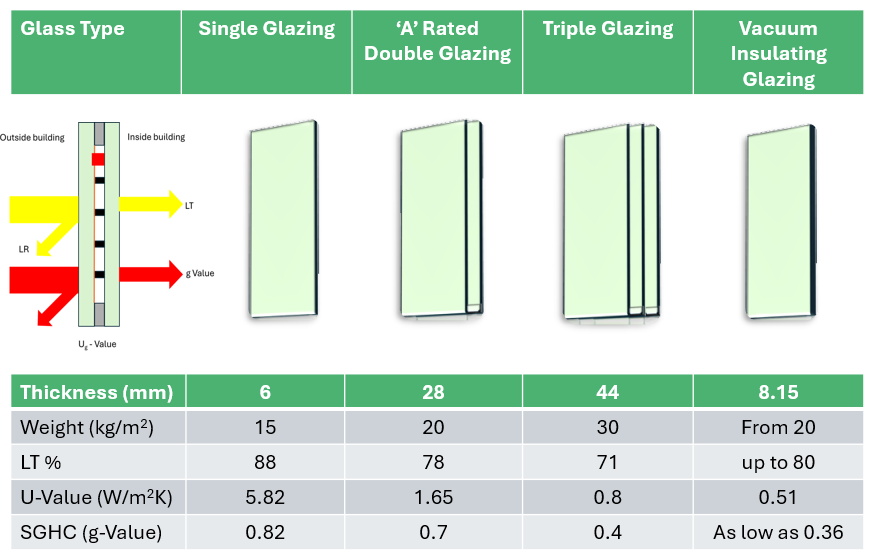

In simple terms, vacuum insulated glazing (or VIG) is made of two panes of glass separated by a 0.15mm vacuum gap. No air means no medium for heat to move through by conduction or convection. The result is an incredibly efficient insulator, far exceeding most conventional systems.

That minimalist structure delivers surprising results. At just over 6mm thick, it’s barely wider than a single pane yet performs better than triple glazing. External noise softens to a background hush, turning city flats and roadside homes into calmer, quieter spaces. For listed buildings and heritage projects, that thin profile is a breakthrough, it brings modern performance without altering traditional frames or sightlines.

Built for the Future

The UK’s Future Homes Standard, due in Autumn 2025, will redefine energy performance for every new build. We’re talking about homes designed to emit up to 80% less carbon than those built today, a leap that demands genuine innovation, not incremental tweaks.

Then come the EPC deadlines: 2027 for privately rented homes to achieve a C rating or above, and 2030 for all rented properties, including social housing. The direction is clear, and the timelines are tight.

Vacuum glazing provides one of the most straightforward routes to compliance. Its outstanding thermal insulation cuts heat loss, easing the burden on heating systems and lowering energy demand from day one. The payoff is immediate: lower bills, steadier comfort, and consistent performance that lasts for decades. For developers and designers weighing upfront investment against long-term gains, it’s a solution that makes both economic and environmental sense.

The Benefits of Vacuum Glazing

Note: Values are approximate and can vary based on specific product configurations.

The performance data tells the story. PassivGlas™ vacuum glazing achieves U-values as low as 0.44 W/m²K, outperforming high-spec double and triple glazing. Light transmission remains high, keeping interiors bright and natural, while sound insulation reaches up to 41dB, muting traffic and street noise.

Because each unit is slimmer and lighter, retrofits become more practical. In many cases, they can be fitted directly into existing frames, avoiding major structural work and the embodied carbon tied to full replacements. It’s a cleaner upgrade that respects both the building and the environment.

Vacuum Glazing: the clear choice for a sustainable future

Vacuum glazing isn’t just another technical innovation, it’s a smarter, leaner way to think about sustainability.

This isn’t just an energy upgrade; it’s a change in perspective. As the UK moves toward a low-carbon future, vacuum glazing offers something that feels both progressive and grounded: clearer views, quieter homes, and a lighter footprint on the planet.

Put simply, it does more with less